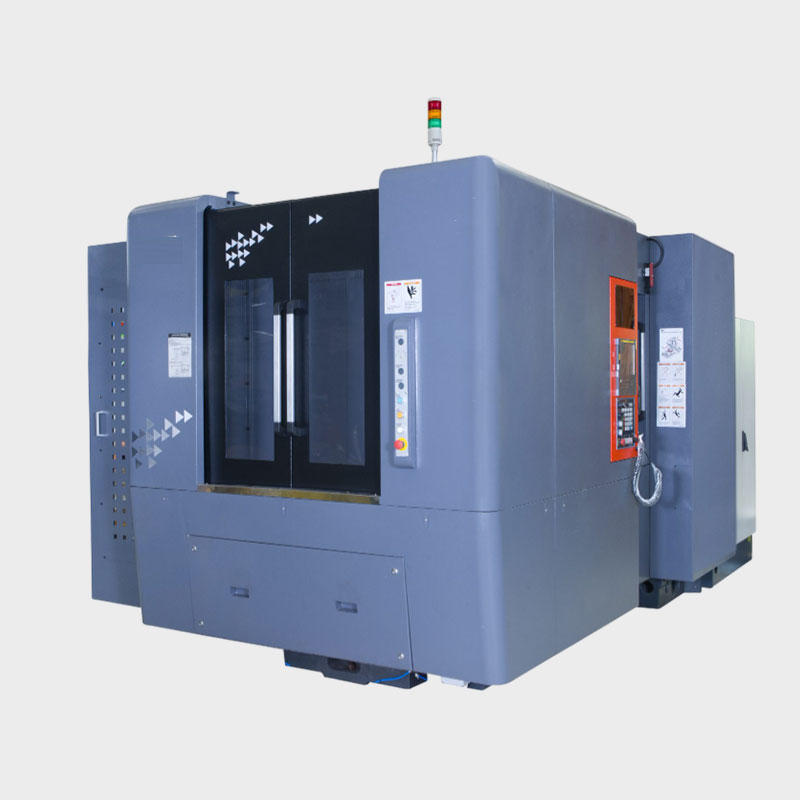

Our BFW HMC (Horizontal Machining Center) Reconditioning service is designed to restore your machine's performance, accuracy, and reliability.

Whether your BFW HMC is suffering from mechanical wear, outdated controls, or loss of precision, we provide comprehensive reconditioning that includes mechanical restoration, electrical system renewal, and precision calibration—bringing your machine back to optimal working condition.

Key Highlights

- Mechanical Overhaul: Complete refurbishment of moving parts including guideways, bearings, ball screws, and spindles.

- Electrical & CNC Refurbishment: Replacement or upgrade of obsolete CNC systems, control panels, and wiring.

- Alignment & Accuracy Restoration: Laser-based leveling, squareness correction, and accuracy tuning.

- Hydraulic & Pneumatic Systems Check: Repair or replacement of fluid systems for smooth operation.

- Parts Replacement: Use of OEM or high-quality compatible spares for long-lasting performance.

- Performance Testing: Full load trials and test machining to validate reconditioning results.

- Extended Machine Life: A smart, cost-effective solution to extend the lifespan and productivity of your BFW HMC.